KEY STRATEGIES FOR SUCCESSFUL PINEAPPLE LEAF FIBER APPLICATION IN PRODUCTION

🌿 From Idea to Production – How to Apply Pineapple Leaf Fiber Effectively?

Pineapple Leaf Fiber (PALF) is pioneering a new direction for the sustainable textile industry. However, many businesses remain uncertain about integrating this fiber into their existing production processes.

❓ How does pineapple leaf fiber perform on spinning lines?

❓ Does pineapple leaf fiber require special processing?

❓ How can we ensure high-quality products from pineapple leaf fiber?

👉 In this article, we'll share the KEY STRATEGIES to help businesses apply pineapple leaf fiber most efficiently and effectively.

🔥 1. How Does Pineapple Leaf Fiber Perform on Spinning Lines?

✅ 1.1. Which Fabric Types Can Pineapple Leaf Fiber Be Used In?

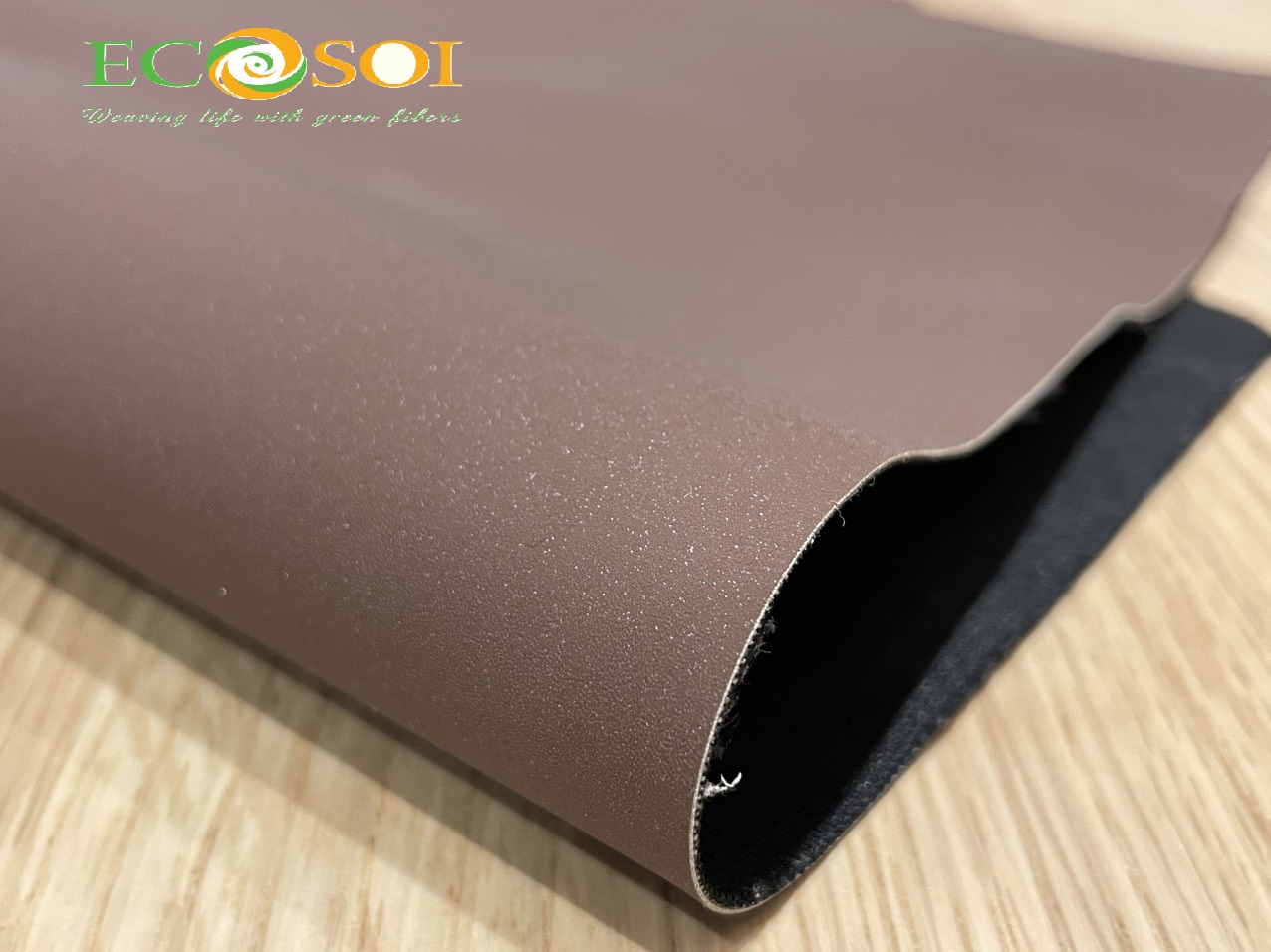

Pineapple leaf fiber can be woven into fabric or used in nonwoven fabric technology, depending on business requirements.

💡 Common applications of pineapple leaf fiber:

✅ Woven and knitted fabrics: Creating fabrics for fashion, bedding, and curtains.

✅ Nonwoven fabrics: Producing fabric bags, soundproofing materials, and wipes.

✅ Blended fabrics: Combining with cotton, viscose, and modal to improve softness and durability.

✅ 1.2. Does Pineapple Leaf Fiber Require Machinery Adjustments?

The good news is that pineapple leaf fiber can be integrated into existing production lines without significant machinery changes.

📌 Technical requirements:

🔹 Spinning machines may require a slight speed adjustment compared to synthetic fibers.

🔹 When blending with cotton or viscose, adjust the appropriate ratio (20-40% pineapple leaf fiber is optimal).

🔹 Weaving processes require humidity control to prevent fiber breakage.

👉 Solution: Our technical team is ready to assist with adjustments and testing on your production line.

🔥 2. How to Process Pineapple Leaf Fiber for High Quality

✅ 2.1. High-Quality Pineapple Leaf Fiber Production Process

1️. Pineapple leaf harvesting – Using leaves from mature pineapple plants for assured toughness.

2️. Mechanical fiber extraction – Avoiding chemicals, preserving fiber structure.

3️. Softening and antibacterial treatment – Enhancing fiber softness while maintaining durability.

4️. Spinning and weaving – Can be woven alone or blended with cotton, hemp, or viscose.

5️. Quality inspection – Ensuring compliance with export standards like GOTS, OEKO-TEX, and EU EcoLabel.

✅ 2.2. How to Blend Pineapple Leaf Fiber for Optimal Quality

Pineapple leaf fiber can be used alone or blended with other fibers for enhanced properties.

📌 Optimal blending ratios:

✔ Pineapple leaf fiber + Cotton (30-50%) → Increased durability while maintaining softness.

✔ Pineapple leaf fiber + Viscose (20-40%) → Suitable for fashion fabrics, improving fabric lightness.

✔ Pineapple leaf fiber + Polyester (10-30%) → Enhanced wrinkle resistance, suitable for industrial fabrics.

👉 Solution: We provide pre-blended fabric samples for easy testing on your products.

🔥 3. How to Ensure Pineapple Leaf Fiber Products Meet International Standards

✅ 3.1. Essential Certifications for Exporting Pineapple Leaf Fiber Products

For international market access, businesses need to secure the following certifications:

🔹 OEKO-TEX Standard 100: Confirming product safety for consumers.

🔹 GOTS (Global Organic Textile Standard): Organic certification for easier export to Europe.

🔹 EU EcoLabel: Recognized in 27 EU countries, confirming environmental friendliness.

💡 By using pineapple leaf fiber, businesses can achieve these certifications more easily than with synthetic fibers or cotton.

✅ 3.2. How to Optimize Quality Inspection Processes

💡 To ensure product quality, focus on these factors:

✔ Tensile strength: Ensuring fiber doesn't break during weaving.

✔ Absorbency: Critical for towels and apparel.

✔ Antibacterial properties: If used in fashion, preventing mold during storage.

👉 Solution: We provide quality inspection guidelines and technical documents for easy standard compliance.